Branch Wood Chipper

Effortless Branch Disposal. Instant Biomass Productivity

【Feed Size】: ≤200 mm

【Capacity】: 6t/h

【Application】: Widely used for branch shredding in landscaping, nursery maintenance, and park maintenance

【Power】: Available in Diesel Engine & Electric Motor options.

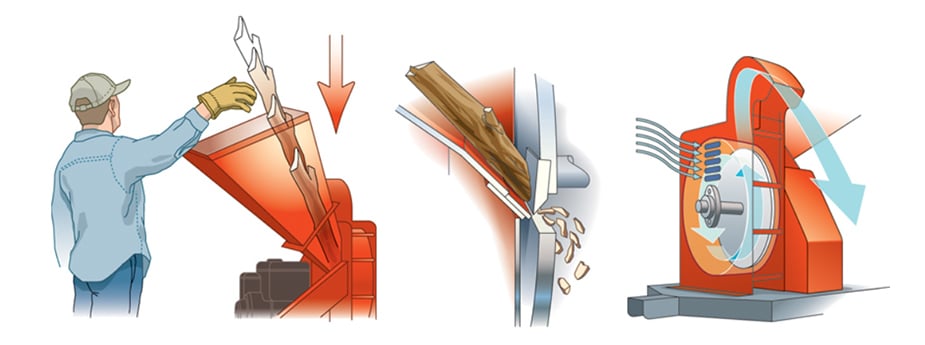

Technique Principle

Engineered for rigorous multi-sector deployment, Guoyu’s Branch Wood Chipper excels in processing untreated green waste across landscaping trimmings, orchard prunings (fruit trees/vines), forestry residues, roadside maintenance, urban green belts, parks, and golf courses. It effortlessly shreds all forms of fresh or dry branches, leaves, twigs, and trunks—no pre-processing needed. The operator-friendly design enables single-pass shredding, transforming waste into valuable raw materials instantly. Output serves as: ground cover mulch, in-field composting, landscaping substrates, organic fertilizer, mushroom cultivation biomass, biofuel for power plants, or industrial materials for MDF, particleboard, and paper production—turning debris into profit streams.

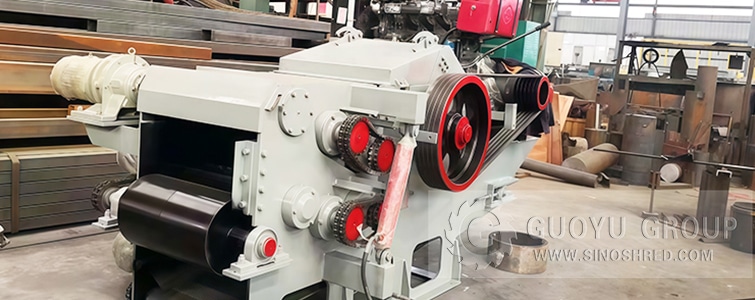

Types of Machine For Sale

GY-1108 Series Branch Wood Chipper

Capacity: 1100-1300kg/h

Fuel Type: Diesel

Max. Feeding Diameter: 6-10cm

Speed: 2800rpm

GY-BC130 Series Branch Wood Chipper

Capacity: 1-2t/h

Power: 32HP Diesel Engine

Main Shaft Speed: 2900r/min

Max. Feeding Diameter: ≤100mm

GY-BC145 Series Branch Wood Chipper

Capacity: 5-6t/h

Power: 102HP/76kW

Max. Feeding Diameter: ≤200mm

Flywheel Speed: 2200rpm

GY-BC175 Series Branch Wood Chipper

Capacity: ≥8t/h

Max Feeding Diameter: ≤350mm

Flywheel Diameter: 750mm(Cutter Roller)

Flywheel Speed: 1600rpm

GY-W-40 Series Small Branch Wood Chipper

Max. Diameter of Feeding: ≤15cm

Power: Diesel (490cc)

Flywheel Diameter: 600mm

Flywheel Turning Speed: 1025rpm

Key Features

Achieve 90-95% volume reduction by blasting wood chips directly into transport trucks via the discharge chute. This eliminates manual loading labor and slashes hauling costs by maximizing payload capacity. Fewer trips mean reduced fuel consumption, lower emissions, and immediate cost efficiency—turning waste into compact, transport-ready biomass.

Highway-ready tires, integrated tow hitch, and a 360° swivel discharge enable instant deployment anywhere—mountains, highways, or urban roads. No setup required: just arrive, connect, and shred. The diesel engine’s protective housing ensures durability while allowing unrestricted operation in remote terrain without burning bans or grid power dependency.

Powered by a turboforce diesel engine with hydraulic load-sensing, it crushes even dense hardwoods non-stop. Built for 24/7 forestry workloads: 600mm cutting blades, real-time engine monitoring, and industrial-grade chassis guarantee uninterrupted processing regardless of branch size or moisture. Ideal for high-volume clearance projects demanding zero downtime.

Key Features

Volume Revolution

Achieve 90-95% volume reduction by blasting wood chips directly into transport trucks via the discharge chute. This eliminates manual loading labor and slashes hauling costs by maximizing payload capacity. Fewer trips mean reduced fuel consumption, lower emissions, and immediate cost efficiency—turning waste into compact, transport-ready biomass.

Absolute Mobility

Highway-ready tires, integrated tow hitch, and a 360° swivel discharge enable instant deployment anywhere—mountains, highways, or urban roads. No setup required: just arrive, connect, and shred. The diesel engine’s protective housing ensures durability while allowing unrestricted operation in remote terrain without burning bans or grid power dependency.

Diesel Dominance

Powered by a turboforce diesel engine with hydraulic load-sensing, it crushes even dense hardwoods non-stop. Built for 24/7 forestry workloads: 600mm cutting blades, real-time engine monitoring, and industrial-grade chassis guarantee uninterrupted processing regardless of branch size or moisture. Ideal for high-volume clearance projects demanding zero downtime.

Processable Wood Varieties

Output Display

Application Scenarios

Working Principle

Guoyu brush wood chippers employ a dual-mechanism shredding process integrating high-speed mechanical cutting with aerodynamic forces. The diesel or electric motor drives a rotor fitted with hardened steel blades that initially fracture branches through direct impact-shearing. Simultaneously, rotational energy generates a cyclonic airflow vortex (>80 m/s) around the blade path.

Material entering the feed throat undergoes:

Primary Fragmentation: Blades forcibly slice and tear fibers (shear force >200 MPa);

Aerodynamic Acceleration: Torn particles become airborne, colliding with rotor hoods and each other at centrifugal velocities;

Secondary Attrition: Impact collisions pulverize semi-processed fragments against tungsten carbide-lined chamber walls.

Optional calibrated screens (Φ5–50mm) ensure output quality:

Particles meeting size criteria eject instantly through discharge airflow;

Oversized fragments recirculate via turbulent eddies for repeated crushing.

This synergy achieves >95% reduction efficiency while minimizing blade wear through distributed energy transfer—optimal for mixed softwoods and hardwoods.

Product Structure

| Technical Aspect | Functional Advantage |

| Impact-shearing blades | Forces material fracture at cell level |

| Cyclonic airflow | Accelerates particles for collision-based attrition |

| Recirculation vortex | Extends residence time for hard fibers |

| Modular screening | Enables chip/sawdust/flake production |

Core Advantages

Feed System: Optimized Material Intake

The foldable feed platform (130cm width) enables rapid setup/stowage, while hydraulic-driven feed rollers (Ø280–600mm) provide constant compression force for bundled branches, eliminating jams and operator intervention. The 390×443mm feed throat accepts trunks up to 32cm diameter, with serrated rollers preventing kickback

Shredding System: Industrial-Grade Fragmentation

Centered on a 600mm hardened steel blade rotor (4–6 HSS dynamic blades + 1 static blade), delivering 1025–2900 RPM impact-shearing. A reinforced crushing chamber (16mm steel plate + internal baffles) contains fragments, while the integrated centrifugal fan (>18m³/sec airflow) accelerates particle collisions for finer output.

Discharge System: Precision Material Handling

Features a 360° rotatable discharge chute (height: 1.6–2.6m) with adjustable trajectory control. High-velocity airflow ejects chips directly into transport vehicles (range: 4–8m), bypassing manual handling. Sieve meshes (optional) calibrate output to 5–50mm.

Mobility & Stabilization: Agile Deployment

A trailered chassis with 165/70R13 highway tires ensures road compliance. Four hydraulic stabilizers auto-level the unit on slopes ≤25°, with a hydraulic jack enabling hitch-free positioning. Total weight: <1.8T for single-axle towing.

Technical Specifications

| Parameter | GY-1108 | GY-W-40 | GY-BC130 | GY-BC145 | GY-BC175 |

| Model Type | Trailed Chipper | Trailed Mobile | Trailed Mobile | Industrial Trailer | Heavy-Duty Chipper |

| Power Source | Diesel | Diesel (490cc) | Diesel | Diesel | Diesel (Turbo) |

| Engine Power | 22 HP / 16 kW | 40 HP / 30 kW | 32 HP / 24 kW | 102 HP / 76 kW | 197 HP / 147 kW |

| Max. Feeding Dia. | 6-10 cm | ≤15cm | ≤100mm | ≤200 mm | ≤350 mm |

| Flywheel Diameter | – | 600 mm | 300 mm (Cutter Roller) | 500 mm (Cutter Roller) | 750 mm (Cutter Roller) |

| Flywheel Speed | 2800 rpm | 1025 rpm | 2900 rpm | 2200 rpm | 1600 rpm |

| Blade System | 3 Blades | 2 or 4 Blades (Optional) | 4 Movable + 1 Fixed | 4 + 1 | 6 + 1 |

| Feeding System | Manual Hydraulic Feed | Hydraulic | Hydraulic | Hydraulic | Chain-Conveyor (Dual) |

| Feed Control | – | Stop-Reverse-Forward | Forward/Stop/Reverse | Forward/Stop/Reverse | Forward/Stop/Reverse + Remote |

| Discharge Rotation | Manual | 360° Adjustable | 360° Adjustable | 360° Adjustable | 360° Adjustable |

| Output Size | 1.0-2.5 cm | 3-5 cm | Not Specified | Not Specified | Not Specified |

| Capacity | 1,100-1,300 kg/h | 1-3t/h | 1-2 t/h | 5-6 t/h | ≥8 t/h |

| Hydraulic Tank | Not Specified | 26 L | 25 L | 25 L | 50 L |

| Weight | 530 kg | 780 kg (Packaged) | ~800 kg (Est.) | 2400kg | 5500kg |

| Mobility Features | Trailer Hitch | 165/70R13 | 13″ Alloy Wheels | 15″ Alloy Wheels | 16″ Wheels + 4 Hyd. Stabilizers |

| Smart Control | Manual Only | Hydraulic Auto-Stop | Intelligent Feeding | Intelligent Feeding | Intelligent Feeding |

Shipment Display

Case Study

Why Choose Guoyu Machinery

- Precision-Engineered Durability:

Guoyu chippers (like the GY-6175) deploy military-grade components: HSS dual-edge blades (60+ HRC hardness), 750mm reinforced cutting rotors, and ±25° slope-capable chassis. Rigorously tested in forestry extremes (-20°C to 55°C), they deliver 4,000+ hours MTBF (Mean Time Between Failures)—tripling industry averages.

- Profit-Driven Innovation:

Our 90-95% volume reduction (e.g., GY-1108 → 1/10 transport volume) slashes hauling costs by $350/load. Patented dual-airflow shredding (W-40 series) boosts biomass yield by 30% while cutting energy use 22% versus rivals—payback achieved in <7 months via fuel/labor savings.

- Global Support Ecosystem:

Operate with zero downtime:

- Free Lifetime Remote Diagnostics via IoT-monitored machines (GY-6145/GY6175)

- 48Hr Global Parts Dispatch (26 global warehouses)

- Certified Field Technicians in 15+ countries

Manufacturing

GUOYU integrates advanced casting and forging processes to produce mission-critical shredder components. Our foundry utilizes sand casting (up to 6-ton parts) and precision investment casting for complex geometries.

Service

At GUOYU, our end-to-end partnership model transforms how you experience industrial machinery. We begin long before installation—collaborating to engineer solutions that precisely align with your operational targets and site constraints.