Wood Shaving Machine

Ultra-Soft Shavings: From Livestock Bedding to Luxury Packaging.

【Feed Size】: 100*50cm ~ 260*90cm

【Capacity】: 150-3000kg/h

【Application】: Ideal for pulp production in paper mills, animal bedding across farms/labs, protective packaging in logistics, and biofuel ignition

【Power】: Available in Diesel Engine & Electric Motor options.

Technique Principle

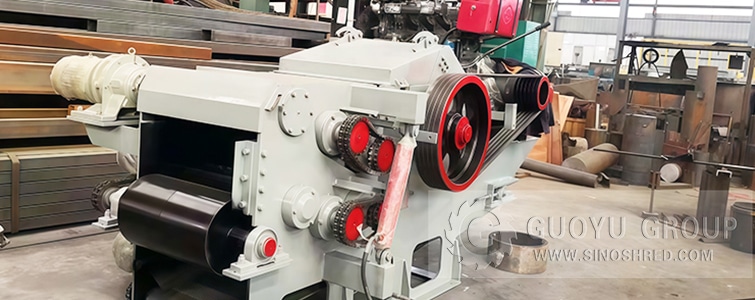

Guoyu Machinery’s shredder-type wood shaving machine utilizes advanced mechanical cutting and crushing technology to process various waste woods (logs, branches, offcuts, etc.) into uniform shavings. This design achieves efficient size reduction while enabling adjustable shaving thickness/size and dust-free operation, transforming scrap material into high-yield, consistently sized recycled material.

Ideal Bedding Solutions for Your Animals

Create the ultimate living environment for your livestock and pets by transforming ordinary wood into superior, dust-free bedding. Different animals require different textures for optimal health: horses need fluffy impact protection, while poultry requires maximum absorbency. Our machines offer precise control over shaving thickness and size, allowing you to produce high-value bedding that rivals top commercial brands. From improving animal welfare to reducing bedding costs, discover how our technology turns wood logs into the ideal solution for your specific application below.

For Horse Beddings

Produce large, fluffy, and soft flakes. Protect horse hooves from hard ground and provide a comfortable, dust-free resting area.

For Poultry Beddings

High absorbency shavings keep the coop dry and significantly reduce ammonia levels. Essential for preventing respiratory diseases in chicks.

For Small Pet Beddings

Create clean, uniform, and sterilized shavings for small pets. Perfect raw material for commercial bedding packaging businesses.

Why Choose SinoShred for Animal Bedding?

✅ Adjustable Thickness (0.3-1.5mm): Customize the flake size for different animals (Thinker for horses, Thinner for chickens).

✅ Soft & Curly Texture: Mimics natural forest floor, ensuring animal comfort.

✅ Dust Extraction Ready: Our machines are designed to work with exhaust systems to minimize dust content.

Types of Machine For Sale

GY-1050-1 Series Wood Shaving Machine

Capacity: 150-200kg/h

Feeding Size: 100*50cm

Power: 11.5kW

Weight: 1100kg

GY-1350-2 Series Wood Shaving Machine

Capacity: 200-300kg/h

Feeding Size: 130*50cm

Power: 19kW

Weight: 1600kg

GY-1450-4 Series Wood Shaving Machine

Capacity: 800-1000kg/h

Feeding Size: 140*50cm

Power: 34.1kW

Weight: 2100kg

GY-1460-4 Series Wood Shaving Machine

Capacity: 600-800kg/h

Feeding Size: 140*60cm

Power: 21.1kW

Weight: 2800kg

GY-1490-4 Series Wood Shaving Machine

Capacity: 1500-2000kg/h

Feeding Size: 140*90cm

Power: 53kW

Weight: 5800kg

GY-2090-4 Series Wood Shaving Machine

Capacity: 2000-2500kg/h

Feeding Size: 200*90cm

Power: 53kW

Weight: 6600kg

GY-2690-6 Series Wood Shaving Machine

Capacity: 3000kg/h

Feeding Size: 260*90cm

Power: 99kW

Weight: 8500kg

GY-2712-4 Series Wood Shaving Machine

Capacity: 3000kg/h

Feeding Size: 270*120cm

Power: 100.1kW

Weight: 8000kg

GY-2850-8 Series Wood Shaving Machine

Capacity: 1300-1800kg/h

Feeding Size: 280*50cm

Power: 69.7kW

Weight: 3500kg

Key Features

The machine utilizes a configurable shaft system (single, twin, or quad shaft) with adjustable German HSS blades. This allows precise control over shaving thickness, shape, and size (thin/thick, long/short) for diverse applications like bedding or board production. Blade quantity is optimized for output requirements.

Engineered for both small users and industrial-scale producers. Compact, affordable single-shaft models serve farms/labs, while large fourth-gen models deliver high-volume output (up to 2000 kg/hour) at low power consumption (50.6 kW total). Output adapts to wood type and feed size.

Features plug-and-play operation requiring no installation. Its advanced cutting mechanism ensures near-dustless shaving production, preventing material scatter for easy bagging and clean workspaces. High material yield, durability from imported components, and suitability for wet/dry timber minimize waste and downtime.

Key Features

Adaptable Shaving Processing

The machine utilizes a configurable shaft system (single, twin, or quad shaft) with adjustable German HSS blades. This allows precise control over shaving thickness, shape, and size (thin/thick, long/short) for diverse applications like bedding or board production. Blade quantity is optimized for output requirements.

Scalable Output Solutions

Engineered for both small users and industrial-scale producers. Compact, affordable single-shaft models serve farms/labs, while large fourth-gen models deliver high-volume output (up to 2000 kg/hour) at low power consumption (50.6 kW total). Output adapts to wood type and feed size.

Optimized Operational Efficiency

Features plug-and-play operation requiring no installation. Its advanced cutting mechanism ensures near-dustless shaving production, preventing material scatter for easy bagging and clean workspaces. High material yield, durability from imported components, and suitability for wet/dry timber minimize waste and downtime.

Processable Wood Diameters

Output Display

Application Scenarios

Working Principle

The core operational principle of a wood shaving machine revolves around rotary shear cutting. Raw wood material (logs, branches, timber waste) is fed into an enlarged hopper. Inside the machine, one or multiple high-speed rotating shafts equipped with hardened steel blades (typically HSS or alloy steel) engage the wood.

As the wood contacts the spinning blades, the cutting edges slice and peel thin layers from the wood surface in a controlled shearing action. Blade geometry and spacing determine shaving thickness and shape (thin curls, wide flakes, or fine strands). The adjustable blade angle and shaft speed allow operators to customize output for applications ranging from livestock bedding to particleboard production.

The rotary mechanism generates centrifugal force, ejecting the cut shavings into a collection chamber or conveyor. Advanced models feature airflow systems or enclosed chambers to minimize dust and ensure shavings fall cleanly for bagging, maintaining operational cleanliness and material yield. Machines process both dry and wet wood without clogging due to robust shaft design and non-stick blade coatings.

Unlike chippers that fragment wood, shaving machines prioritize surface-area maximization, creating lightweight, high-volume output ideal for padding, insulation, or compaction into boards – all while minimizing energy consumption through mechanical efficiency.

Product Structure

| Structure | Function |

| Sturdy Frame Structure | High load-bearing capacity and vibration resistance, ensuring stability during high-intensity wood processing. |

| Large Open Feed Hopper | Enables easy loading of logs, branches, and waste timber without preprocessing or manual cutting. |

| High-Power Drive System | Delivers consistent torque for processing hardwoods/wet wood, minimizing downtime or jamming. |

| Cutting Mechanism Core | Precision shearing action for customizable shaving thickness (paper-thin to coarse curls) and dust reduction. |

| Safety Platforms & Railings | OSHA-compliant operator safety during feeding/maintenance, preventing falls and material ejection hazards. |

| Dedicated Control Panel | Streamlines operational control (start/stop/speed adjustment) with clear status monitoring via gauges. |

| Centrifugal Discharge Chute | Efficient directional ejection of shavings to prevent blockages and ensure material capture. |

| Collection Conveyor/Chute | Automated transport of shavings to bags/containers, eliminating manual handling and loss. |

| Integrated Mobility Features | Simplified repositioning within factories or lumber yards without disassembly. |

Core Advantages

Spacious Overhead Feed Hopper

Guoyu’s widened inlet hopper incorporates deep-wall geometry with smooth internal angles, enabling operators to load whole logs and irregular wood waste without pre-cutting. The unobstructed opening eliminates bridging and reduces manual intervention, while integrated hydraulic or manual ram options (model-dependent) ensure constant material flow into the cutting zone for sustained productivity.

Precision Cutting Drum Assembly

At the machine’s core lies a heavy-duty rotor mounted with customizable German HSS blades. This hardened steel drum’s engineering allows operators to adjust blade projection and angle for specific shaving dimensions – from ultra-thin packaging flakes to thick animal bedding curls. Reinforced shaft bearings maintain stability at 1,000+ RPM speeds, while quick-release blade clamps facilitate sharpening or replacement during shift changes.

Multi-Unit Drive Train System

Guoyu’s modular power configuration employs parallel-mounted high-torque electric motors with synchronized gearbox coupling. This setup distributes mechanical load across multiple drives, preventing overloads during hardwood processing and enabling scalable power (15kW–200kW+) without re-engineering the frame. IP55-rated enclosures with thermal sensors protect motors from dust ingress in harsh milling environments.

Centrifugal Output Conveyor

Positioned directly below the cutting chamber, the inclined conveyor leverages rotational momentum to eject shavings. Its deep-cupped paddles and sealed sidewalls contain dust within the transfer path, while variable-speed drives allow operators to modulate discharge rates matching baling or bagging equipment. Reinforced scrapers beneath the belt prevent material buildup that typically causes conveyor misalignment.

Technical Specifications

| Model | GY-1050-1 | GY-1350-2 | GY-1450-4 | GY-1460-2 | GY-1460-4 | GY-1490-4 | GY-2090-4 | GY-2850-8 | GY-2690-6 |

| Total Power | 11.5kW | 19kW | 34.1kW | 21.1kW | 35.1kW | 53kW | 53kW | 69.7kW | 99kW |

| Feeding Inlet Size | 100×50cm | 130×50cm | 140×50cm | 140×60cm | 140×60cm | 140×90cm | 200×90cm | 280×50cm | 260×90cm |

| Output Capacity | 150-200kg/h | 200-300kg/h | 800~1000kg/h | 600-800kg/h | 1200-1500kg/h | 1500-2000kg/h | 2000-2500kg/h | 1300-1800kg/h | 3000kg/h |

| Blade Quantity | Customizable based on shaving size requirements | ||||||||

| Weight | 1100kg | 1600kg | 2100kg | 2800kg | 3300kg | 5800kg | 6600kg | 3500kg | 8500kg |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| (subject to customization) | |||||||||

| Dimensions (L×W×H) | 320×100×140cm | 380×100×160cm | 390×135×140cm | 330×165×150cm | 380×165×155cm | 530×210×220cm | 560×210×220cm | 150×600×130cm | 640×200×210cm |

Shipment Display

Case Study

Why Choose Guoyu Machinery

- Scalable Output Precision Engineering:

Guoyu offers 9+ factory-calibrated models (YM1050-1 to YM2690-6) with granular output scaling – from 150kg/h to 3,000kg/h capacity. Unlike generic “one-size-fits-all” solutions, each model integrates dedicated power trains (11.5kW to 99kW) and hopper geometries precisely tuned for target throughput. This eliminates underutilized equipment or bottlenecks in expanding operations.

- Dynamic Blade Customization System:

While competitors use fixed blade configurations, Guoyu’s patented shaft assembly allows custom blade density/spacing adjustments per shaving specification. Operators optimize for paper-thin packaging flakes or thick bedding curls without machine swaps. Coupled with German HSS steel blades, this cuts retooling costs 40% while ensuring uniform output across hardwood, wet timber, or softwoods.

- High-Yield Industrial DNA:

Engineered for 24/7 duty cycles, Guoyu units achieve 20-30% higher yield vs. industry averages through centrifugal ejection tech and minimized in-process dust loss (e.g., 3000kg/h peak output in YM2690-6). All models feature reinforced frames, thermal-protected motors, and <0.5% downtime – translating to ROI within 8 months for high-volume users.

Manufacturing

GUOYU integrates advanced casting and forging processes to produce mission-critical shredder components. Our foundry utilizes sand casting (up to 6-ton parts) and precision investment casting for complex geometries.

Service

At GUOYU, our end-to-end partnership model transforms how you experience industrial machinery. We begin long before installation—collaborating to engineer solutions that precisely align with your operational targets and site constraints.