Mushroom Wood Shredder

Steady Power, Premium Chips: The Balanced Choice for Mushroom Cultivation

【Feed Size】: 280-560 mm

【Capacity】: 6-20t/h

【Application】:Widely applicable to the production of mushroom materials, agaric materials, strain materials, machine-made charcoal, biomass pellets, etc.

【Power】: Available in Diesel Engine & Electric Motor options.

What is Mushroom Wood Chipper?

A mushroom wood chipper, essentially a specialized wood crusher, processes materials like logs, branches (1-45cm in diameter) into 3-30mm sawdust or particles via high-speed rotating blades. Its key trait lies in serving mushroom cultivation – crushed wood acts as a substrate for mycelium growth of shiitake, oyster mushrooms, etc. . It also suits fertilizer production and biomass energy, with adjustable particle sizes, compact structure, and low energy consumption.

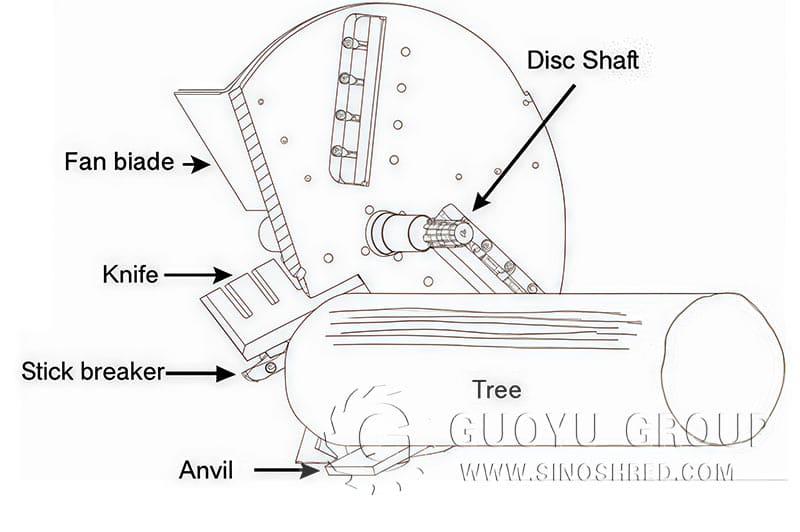

Technique Principle

The Mushroom Wood Chipper operates on a precision rotary shear-cutting mechanism powered by a directly coupled motor for maximum torque transfer. Key to its efficiency is the engineered rotor system, dynamically balanced with weighted hammer plates rotating at high speed. Logs are fed radially onto the cutting disc, where strategically positioned blades slice material against fixed counter-edges. Vibration control is critical: alignment of motor/rotor axes, meticulous hammer mass distribution (±5g tolerance), and isolation mounts ensure stable operation. This creates uniformly fragmented wood chips ideal for mycelium colonization, optimizing substrate preparation for mushroom cultivation. Output size depends on adjustable screen apertures.

Types of Machine For Sale

Key Features

Engineered rotor assembly with dynamically balanced hammer plates ensures smooth, near-vibration-free operation. Meticulous hammer mass distribution (±5g tolerance) and high-precision motor-rotor alignment prevent harmful vibrations, reducing stress on components and improving machine longevity while ensuring operator comfort.

Utilizes powerful motor direct-coupled to the cutting rotor for maximum torque transfer and energy efficiency. High-RPM rotation generates immense kinetic cutting force, enabling fast processing of hard mushroom logs into consistently sized chips, maximizing throughput and productivity for substrate preparation.

Designed for simple maintenance: symmetrical hammer wear allows for easy grouped replacement without downtime; accessible wear parts and intuitive assembly simplify service. Robust construction minimizes downtime and lowers operating costs, maximizing equipment uptime and reliability in demanding production environments.

Key Features

Precision-Balanced Rotor System

Engineered rotor assembly with dynamically balanced hammer plates ensures smooth, near-vibration-free operation. Meticulous hammer mass distribution (±5g tolerance) and high-precision motor-rotor alignment prevent harmful vibrations, reducing stress on components and improving machine longevity while ensuring operator comfort.

High-Efficiency Direct-Drive Cutting

Utilizes powerful motor direct-coupled to the cutting rotor for maximum torque transfer and energy efficiency. High-RPM rotation generates immense kinetic cutting force, enabling fast processing of hard mushroom logs into consistently sized chips, maximizing throughput and productivity for substrate preparation.

Optimized Serviceability & Durability

Designed for simple maintenance: symmetrical hammer wear allows for easy grouped replacement without downtime; accessible wear parts and intuitive assembly simplify service. Robust construction minimizes downtime and lowers operating costs, maximizing equipment uptime and reliability in demanding production environments.

Processable Wood Varieties

Output Display

Application Scenarios

Working Principle

- Feeding: Logs or large pieces of mushroom cultivation wood are manually or mechanically fed radially (into the side) onto the rotating cutting disc inside the feed chute/hopper.

- Initial Capture & Positioning: As the disc spins at high speed, strategically placed blades or flails (hammers) on the rotor initially capture and center the wood against the cutting surface.

- Shear Cutting: The high-speed rotor forces the wood against fixed counter blades (anvils) or guides located around the edge of the cutting chamber. The combined action of the moving rotor blades/hammers and these stationary edges creates a powerful shearing action, slicing the wood into chunks.

- Impact Fragmentation: Smaller chunks or pieces contacting the spinning hammers are further shattered and fragmented into smaller pieces through high-kinetic-energy impact blows.

- Particle Size Control: The fragmented wood pieces are propelled towards the inner perimeter of the cutting chamber. They pass through a perforated screen/sieve (often interchangeable) surrounding the rotor. The size of the holes in this screen determines the maximum allowable size of the final wood chip output.

- Output & Collection: Chips small enough to pass through the screen are ejected by the rotor’s centrifugal force and airflow out of the discharge chute. They are collected directly into bags, bins, or conveyed to the next stage of mushroom substrate preparation (e.g., mixing, bagging, sterilization).

- Oversize Recirculation: Wood fragments too large to pass through the screen are retained inside the cutting chamber. The spinning rotor continuously recirculates these pieces, subjecting them to repeated cutting and impact blows until they are sufficiently reduced in size to pass through the screen. This ensures uniform chip sizing.

Product Structure

| Structure | Functional Advantage |

| High-Precision Direct Drive (Motor rigidly coupled to rotor shaft) | Eliminates power transmission losses & minimizes vibration sources; Ensures maximum torque delivery for consistent high-RPM cutting |

| Dynamically Balanced Rotor Assembly (Heavy-duty steel disc with replaceable hammer plates) | Creates smooth rotation & near-vibration-free operation; Distributes kinetic energy evenly for efficient, low-stress cutting |

| Radial Feed Hopper/Chute | Allows controlled, gravity-assisted wood feeding directly into the cutting zone; Optimizes safety and material flow efficiency |

| Hardened Cutting Chamber | Houses impact/shear cutting action; Reinforced lining withstands abrasion, minimizing wear and extending lifespan |

| Adjustable Screen/Sieve (Perforated metal casing surrounding rotor) | Controls final chip size uniformity (interchangeable meshes); Recirculates oversized chips until desired particle size is achieved |

| Symmetrical Hammer Sets | Allows grouped rotation/replacement (1:2 ratio); Balances rotor, reduces downtime, and simplifies maintenance |

| Dual-Access Service Doors | Enables quick inspection, hammer replacement, screen changes, and cleaning without disassembly |

| Heavy-Duty Isolation Mounts | Decouples machine vibration from the frame/floor; Protects foundations and reduces operational noise |

| Centrifugal Discharge Chute | Leverages rotor airflow to eject finished chips rapidly; Enables continuous collection into bags/conveyors |

| Robust Welded Steel Frame | Provides structural rigidity to maintain rotor alignment; Absorbs operational stresses, ensuring long-term durability |

Core Advantages

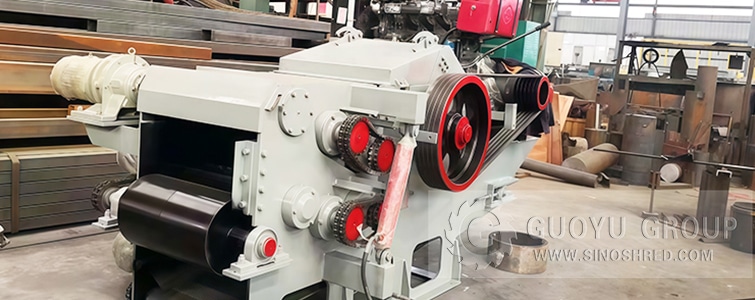

Large-Scale Rotational Assembly

A massive circular metal component welded centrally to a sturdy cylindrical shaft. This assembly, mounted on supports, forms the heavy-duty rotational mass crucial for shearing wood. Its significant size and exposed mounting suggest focus on durability.

Stabilized Base & Mounting Frame

The large circular component dominates but is clearly mounted firmly on a substantial support stand. This dedicated, sturdy base provides critical stability, isolating the machine’s intense rotational forces and vibrations.

Integrated Power Transmission System

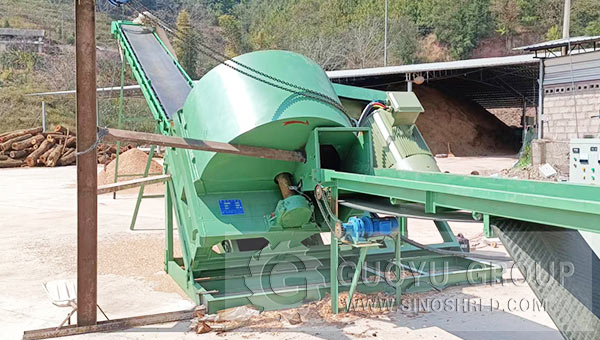

A large, prominent black motor securely mounted directly onto the machine’s rigid green frame near the processing chamber. This direct positioning minimizes drive losses and ensures efficient torque transfer to the cutting rotor.

Optimized Material Intake Structure

An inclined hopper integrated with the sturdy frame. The inclination facilitates smooth, gravity-assisted feeding into the processing zone, while robust welded joints and fasteners ensure structural integrity under heavy material flow.

Technical Specifications

| Model | Feed Opening Size(mm) | Output Capacity(t/h) | Motor Power(kW) | Spindle Speed(r/min) | Machine Weight(kg) | Blade Count | Overall Dimensions(mm) |

| GY-420 | 170×150 | 0.5-1.2 | 7.5 | 2800 | 130 | 4 | 1200×550×750 |

| GY-500 | 200×170 | 1.5 | 11 | 2800 | 210 | 4 | 1500×640×820 |

| GY-600 | 220×180 | 2 | 18.5 | 2700 | 320 | 4 | 1500×700×900 |

| GY-700 | 230×190 | 2.5 | 22 | 2100 | 450 | 4 | 1850×830×1050 |

| GY-800 | 230×200 | 3-4 | 37 | 2000 | 600 | 6 | 1950×900×1100 |

| GY-1000 | 280×280 | 5-8 | 90 | 1000 | 800 | 8 | 2000×1870×1500 |

| GY-1200 | 360×360 | 8-10 | 110 | 1000 | 1600 | 8 | 2500×1200×1300 |

| GY-1500 | 460×460 | 12-15 | 132 | 1000 | 2200 | 8 | 2800×1350×1600 |

| GY-1800 | 560×560 | 15-20 | 160 | 900 | 3000 | 12 | 2900×1450×1700 |

Shipment Display

Case Study

Manufacturing Details

Why Choose Guoyu Machinery

- Precision-Engineered Stability:

Guoyu chippers feature dynamically balanced rotors (±5g tolerance) and motor-rotor direct coupling, minimizing vibration. This precision reduces structural stress, extends machine lifespan by 30%, and ensures smooth operation even at 2800 RPM – critical for high-volume substrate processing with consistent chip quality.

- Unmatched Operational Efficiency:

Engineered for high-yield output (up to 20 t/h) and minimal downtime, our symmetrical hammer system allows 1:2 blade replacement without rotor disassembly. Combined with wear-resistant steel chambers and dual-access doors, maintenance time is reduced by 50%, maximizing production uptime.

- Application-Optimized Engineering:

From radial gravity-fed hoppers ensuring safe feeding to interchangeable screens (3-30mm chip calibration), every component is purpose-built for mushroom cultivation. The heavy-duty welded frame withstands 24/7 operation, while isolation mounts protect your facility – delivering farm-to-substrate reliability.

Manufacturing

GUOYU integrates advanced casting and forging processes to produce mission-critical shredder components. Our foundry utilizes sand casting (up to 6-ton parts) and precision investment casting for complex geometries.

Service

At GUOYU, our end-to-end partnership model transforms how you experience industrial machinery. We begin long before installation—collaborating to engineer solutions that precisely align with your operational targets and site constraints.