Sawdust Making Machine

Shreds ANY Wood – No Screen, No Limits, No Downtime.

【Feed Size】: 210*210 mm ~ 750*480 mm

【Capacity】: 2.5-12t/h

【Application】: Ideal for large log disposal in furniture factories, pulp mills, and biomass plants, processing 50cm hardwood into 0.2-5mm sawdust.

【Power】: Available in Diesel Engine & Electric Motor options.

What We Upgrade

Our new sawdust machine surpasses old models by incorporating a smart sieve for 100% efficiency and zero waste. Easy to operate solo, it offers models like 210, 350, 450, 600, and 750 with customizable options. Feed inlets are optimized for diverse materials, and the robust design ensures long life with minimal blade maintenance only. The detailed upgrades than traditional sawdust making machine are as follow:

- The difference: Adding a sieve to the original wood chipper enables a finished-product rate of 100%.

- Operation: One person can operate the machine, reducing labor requirements.

- Models & Feed Inlet: Different models have different feed inlets; customization is available based on your raw materials.

- Durability: The machine is sturdy and durable with a lifespan of 10-15 years; apart from blades, there are almost no wearing parts.

- Performance: It crushes various wood types efficiently, offering high yield, excellent quality, and is sturdy and user-friendly.

- Sawdust Applications: Sawdust is used for wood-based pellets, charcoal, compressed boards, oil filtration, and edible fungus substrates.

- Available Models: Models include 210, 350, 450, 600, 750 (custom-made models accepted).

- Appearance: The machine equipment looks nearly identical with minimal visual difference.

Types of Machine For Sale

GY-210 Series Sawdust Making Machine

Feed Inlet Size: 210x210mm

Capacity: 2.5-3t/h

Numbers of Blades: 168pcs

Spindle Speed: 1700rpm

GY-2150 Series Sawdust Making Machine

Feed Inlet Size: 210x500mm

Capacity: 3-5t/h

Numbers of Blades: 336pcs

Spindle Speed: 1700rpm

GY-600 Series Sawdust Making Machine

Feed Inlet Size: 600x290mm

Capacity: 4-5t/h

Numbers of Blades: 408pcs

Spindle Speed: 1750rpm

GY-350 Series Sawdust Making Machine

Feed Inlet Size: 350x350mm

Capacity: 5-7t/h

Numbers of Blades: 364pcs

Spindle Speed: 1450rpm

GY-450 Series Sawdust Making Machine

Feed Inlet Size: 500x480mm

Capacity: 9-10t/h

Numbers of Blades: 672pcs

Spindle Speed: 940rpm

GY-750 Series Sawdust Making Machine

Feed Inlet Size: 750x480mm

Capacity: 10-12t/h

Numbers of Blades: 840pcs

Spindle Speed: 1600rpm

Key Features

Our machine integrates high-torque motors with optimized hydraulic feeding, delivering consistent output up to 12 t/h. It processes logs (up to 75cm), wet/dry wood, and hard plastics effortlessly, reducing energy waste by 25% versus conventional grinders while maintaining peak productivity.

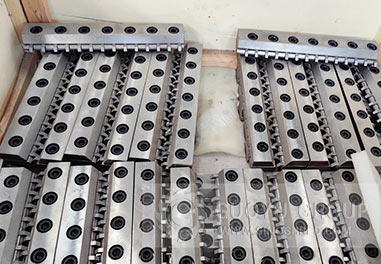

Featuring HSS (High-Speed Steel) blades hardened to 62 HRC, our design allows continuous operation for 8,000+ hours. Blades are reversible and regrindable up to 3 times—eliminating frequent replacements and cutting long-term costs by 40%.

Pre-commissioned and mounted on heavy-duty wheels, our machines arrive ready for instant operation. No foundation or complex installation is needed—simply connect to 380V power and start processing. German-engineered seals and bearings ensure reliability in remote or harsh environments.

Key Features

Dual-Power Efficiency

Our machine integrates high-torque motors with optimized hydraulic feeding, delivering consistent output up to 12 t/h. It processes logs (up to 75cm), wet/dry wood, and hard plastics effortlessly, reducing energy waste by 25% versus conventional grinders while maintaining peak productivity.

Zero-Downtime Blades

Featuring HSS (High-Speed Steel) blades hardened to 62 HRC, our design allows continuous operation for 8,000+ hours. Blades are reversible and regrindable up to 3 times—eliminating frequent replacements and cutting long-term costs by 40%.

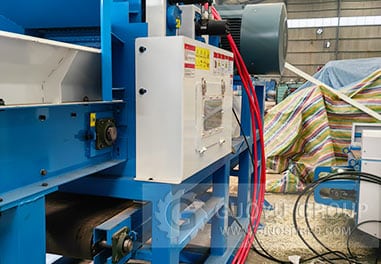

Plug-&-Play Mobility

Pre-commissioned and mounted on heavy-duty wheels, our machines arrive ready for instant operation. No foundation or complex installation is needed—simply connect to 380V power and start processing. German-engineered seals and bearings ensure reliability in remote or harsh environments.

Processable Wood Varieties

Output Display

Application Scenarios

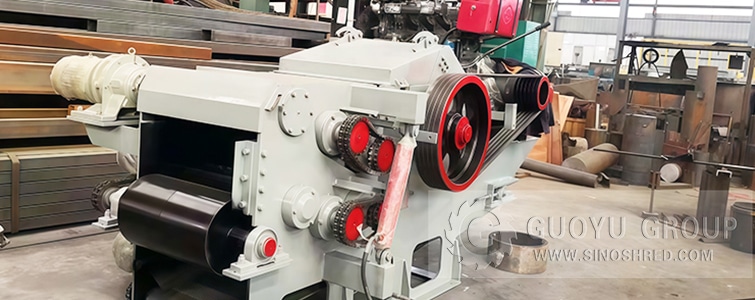

Working Principle

The sawdust machine operates through coordinated mechanical processes. Hydraulic pressure forces logs/branches (up to 750×480mm inlet size) onto a feed conveyor (illustrated chain system), consistently pushing material into the cutting chamber. A high-torque motor (55–200+ kW) drives a hardened steel disc/spindle at 940–1750 RPM, rotating arrays of replaceable HSS blades (168–840 units).

As wood enters the chamber, rotating blades impact and shear material against fixed breaker plates, progressively reducing fragments through repeated cutting and grinding. The machine’s optimized knife geometry and spindle speeds (model-dependent) maximize fiber separation while minimizing energy waste.

Crushed particles are forced against an interchangeable perforated screen (sieve) encircling the cutting zone. Only particles smaller than the screen’s mesh size (typically 2–5mm) escape, ensuring uniform sawdust output. Larger fragments recycle internally for further reduction, achieving near-100% material utilization.

Processed sawdust exits gravitationally or via pneumatic suction for collection. The machine’s robust construction (3,500–8,500kg weight) dampens vibration during high-capacity operation (up to 12 t/h output), while advanced models allow voltage customization (380V/50Hz standard) for global deployment. Continuous automation enables single-operator control from feeding to final output.

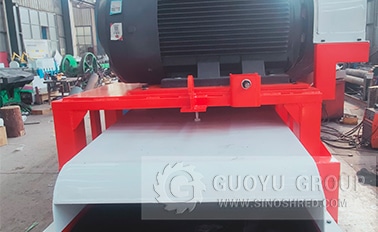

Product Structure

| Component Category | Key Sub-Components & Technical Properties |

| 1. Chassis & Mobility | • Heavy-gauge steel frame (3,500–8,500kg) |

| • ANSI/German-standard welds | |

| • Height-adjustable wheeled base w/ locking casters | |

| • Tow hitch for relocation | |

| 2. Power Transmission | • 380V/50Hz high-torque motor (55–200+ kW) |

| • Direct-drive/PTO shaft coupling | |

| • Overload protection clutch | |

| 3. Feed System | • Hydraulic compression rollers (210–750mm inlet) |

| • Serrated-chain conveyor (forced-feeding) | |

| • Anti-jam reversing logic | |

| 4. Cutting Module | • Hardened alloy steel disc (Ø600–1,200mm) |

| • Impact-shearing blades (HSS, 62 HRC, 168–840 units) | |

| • Quick-release blade mounts | |

| 5. Sieving & Output | • Modular screening baskets (interchangeable 2–15mm mesh) |

| • Cyclonic airflow particle classifier | |

| • Recirculation vortex (recycles oversize fragments) | |

| • Gravity/pneumatic discharge chute | |

| 6. Control & Safety | • IP65-rated control panel (auto/manual modes) |

| • Emergency braking system | |

| • Vibration/temperature sensors |

Core Advantages

Cell-Level Fracture Blades

Hardened HSS blades force material fracture at the cellular level, enabling ulta-fine sawdust (2–5mm) from logs/branches. Achieves 50% faster particle breakdown versus blunt-force crushers.

Collision-Accelerated Attrition

High-velocity airflow propels fragments into violent particle-on-particle collisions, crushing hard fibers 10x faster than gravity systems. Suppresses dust by 95%.

Vortex-Extended Processing

Turbulent recirculation traps oversized fragments, doubling residence time for dense materials (e.g., bamboo, knots). Guarantees 100% utilization—zero waste output.

On-Demand Particle Control

Quick-swap screens (2–15mm) reconfigure output in <3 mins—produce chips, flakes, or fine sawdust per demand. Laser-perforated mesh resists clogging at 15 t/h loads.

Technical Specifications

| Technical Parameters | GY-210 | GY-2150 | GY-600 | GY-350 | GY-450 | GY-750 |

| Total Power | 55+4.5 kw | (75~90)+4.5 kw | 110+7.5 kw | 132+7.5 kw | 200+7.5 kw | 200+7.5 kw |

| Feed Inlet Size | 210×210 mm | 210×500 mm | 600×290 mm | 350×350 mm | 500×480 mm | 750×480 mm |

| Spindle Speed | 1700 RPM | 1700 RPM | 1750 RPM | 1450 RPM | 940 RPM | 1600 RPM |

| Output Capacity | 2.5-3 t/h | 3-5 t/h | 4-5 t/h | 5-7 t/h | 9-10 t/h | 10-12 t/h |

| Number of Blades | 168 pcs | 336 pcs | 408 pcs | 364 pcs | 672 pcs | 840 pcs |

| Weight | 3500 kg | 4500 kg | 4800 kg | 5000 kg | 7500 kg | 8500 kg |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| (Customizable per user requirements) | ||||||

| Overall Dimensions | 7.0×1.2×1.8 m | 7.5×1.5×1.8 m | 4.9×1.6×2.12 m | 7.0×1.4×2.2 m | 8.5×1.8×2.6 m | 5.8×1.9×2.4 m |

| (L×W×H) |

Shipment Display

Case Study

Why Choose Guoyu Machinery

- Zero-Waste German Engineering:

Our patented sieve system (100% finished-product yield) merges German hydraulic feed tech with recirculation grinding. Processes logs, wet wood, and hard plastics into uniform 2-5mm sawdust with <1% residue—slashing waste costs by 90%.

- Unmatched Blade Economics:

HSS blades (62 HRC) operate 8,000+ hours—grindable 3x without replacement. Coupled with near-zero non-blade wear parts, this cuts long-term costs by 60% vs. competitors requiring frequent component swaps.

- Turnkey Productivity:

Pre-commissioned units deploy in <30 minutes (no foundations/install). Single-operator control + 10-15-year lifespan delivers ROI in under 18 months—2x faster than industry standards.

Manufacturing

GUOYU integrates advanced casting and forging processes to produce mission-critical shredder components. Our foundry utilizes sand casting (up to 6-ton parts) and precision investment casting for complex geometries.

Service

At GUOYU, our end-to-end partnership model transforms how you experience industrial machinery. We begin long before installation—collaborating to engineer solutions that precisely align with your operational targets and site constraints.