Wood Chipper

97% Perfect Chips. Maximize Wood Value: Pulp, Board, Biofuel Ready – Cut Transport & Waste Costs.

【Feed Size】: 160*400 mm ~ 450*700 mm

【Capacity】: 3-20t/h

【Application】: Essential for pulp/paper mills, panelboard (MDF/OSB) plants, biofuel producers, and landscaping, transforming wood waste into uniform industrial-grade chips.

【Power】: Available in Diesel Engine & Electric Motor options.

Core Functions & Industrial Value

Resource Optimization

- Transforms low-value waste (branches, slabs ≤120mm via drum chippers) and logs (via high-accuracy disc chippers) into ≥97% qualified chips (for disc type).

- Directly boosts pulp/paper cooking efficiency and MDF/OSB panel density uniformity.

Economic & Environmental Impact

- Cuts raw material transport costs by >30% (mobile units) and landfill disposal fees.

- Enables circular economy: chips power biofuel (18 MJ/kg), mulch production, and pulp/board manufacturing.

Types of Machine For Sale

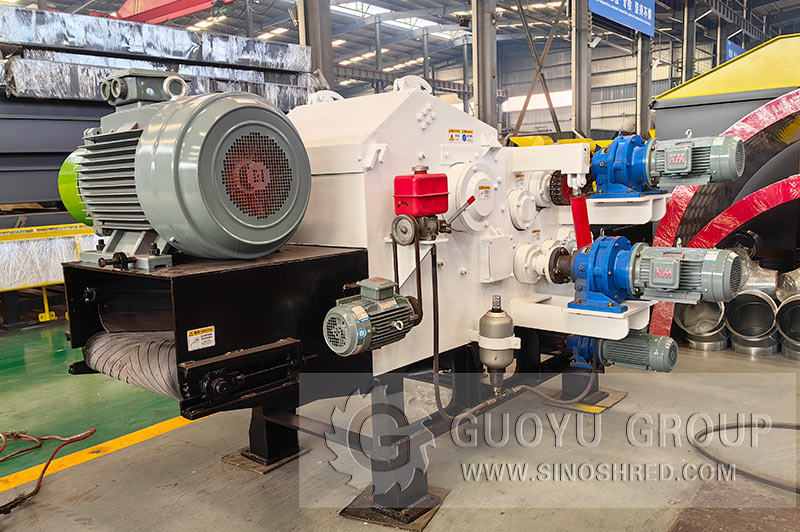

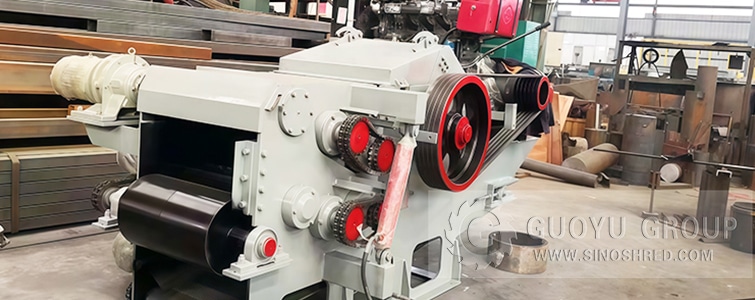

Drum Wood Chipper

Drum Wood Chipper processes logs, branches, slabs & bamboo into uniform industrial chips. Features hydraulic feed rollers for variable sizing, welded steel base for stability, and post-cut screening — optimized for pulp/panel mills with robust, low-maintenance operation.

Drum Wood Chipper

Drum Wood Chipper processes logs, branches, slabs & bamboo into uniform industrial chips. Features hydraulic feed rollers for variable sizing, welded steel base for stability, and post-cut screening — optimized for pulp/panel mills with robust, low-maintenance operation.

GY-216 Series Drum Wood Chipper

Capacity: 7-8t/h

Feeding Size: 230*500mm

Power: 55-60kW

Weight: 4.1t

GY-218 Series Drum Wood Chipper

Capacity: 10-15t/h

Feeding Size: 300*680mm

Power: 90-110kW

Weight: 6.9t

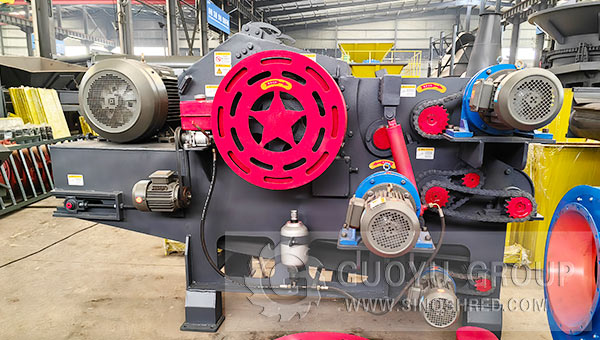

Disc Wood Chipper

Disc Wood Chipper delivers high-precision industrial chips (≥97% uniformity) from logs. Features spiral knives on a rotating disc, flexible drive options (belt/direct), adjustable cut dimensions, and horizontal/vertical discharge — engineered for pulp, MDF, and OSB production efficiency.

Disc Wood Chipper

Disc Wood Chipper delivers high-precision industrial chips (≥97% uniformity) from logs. Features spiral knives on a rotating disc, flexible drive options (belt/direct), adjustable cut dimensions, and horizontal/vertical discharge — engineered for pulp, MDF, and OSB production efficiency.

Mobile Integrated Wood Chipper

Mobile hammer-mill crusher processes logs, demolition waste, and metal-contaminated wood (furniture/doors) into uniform fragments. Tolerates nails/iron, features on-board screening, and enables on-site recycling — eliminating transport costs for construction/demolition debris.

Mobile Integrated Wood Chipper

Mobile hammer-mill crusher processes logs, demolition waste, and metal-contaminated wood (furniture/doors) into uniform fragments. Tolerates nails/iron, features on-board screening, and enables on-site recycling — eliminating transport costs for construction/demolition debris.

Building Template Crusher

Specialized crusher for construction waste like formwork & pallets. Efficiently shreds wood with embedded nails/rebar while self-cleaning metal contaminants via integrated magnets — enabling on-site recycling of complex demolition materials.

Building Template Crusher

Specialized crusher for construction waste like formwork & pallets. Efficiently shreds wood with embedded nails/rebar while self-cleaning metal contaminants via integrated magnets — enabling on-site recycling of complex demolition materials.

Tree Stump Crusher

Heavy-duty solution for giant stumps (≤2.2m dia.), roots, logs & construction waste. Rapidly transforms tough material into biomass-ready fragments (8-100mm) for fuel production or panelboard manufacturing.

Tree Stump Crusher

Heavy-duty solution for giant stumps (≤2.2m dia.), roots, logs & construction waste. Rapidly transforms tough material into biomass-ready fragments (8-100mm) for fuel production or panelboard manufacturing.

Key Features

Transforms low-value forestry waste (branches, slabs, stumps ≤2.2m) and industrial residues into high-demand industrial chips. Reduces raw material transport costs by >30% via mobile units while enabling revenue streams from pulp, biomass, and panel production.

Delivers chips with precision dimensions (15–20mm length, 3–5mm thickness) at ≥97% qualification rates (disc chippers). Ensures optimal pulp cooking efficiency and uniform board density for MDF/OSB, directly boosting downstream manufacturing yield and quality control.

Diverts 100% wood waste from landfills, converting it into carbon-neutral biomass fuel (18 MJ/kg), erosion-control mulch, or recycled panel feedstock. Mobile models enable on-site processing, minimizing emissions from transport while supporting circular economy compliance.

Key Features

Resource-to-Revenue Conversion

Transforms low-value forestry waste (branches, slabs, stumps ≤2.2m) and industrial residues into high-demand industrial chips. Reduces raw material transport costs by >30% via mobile units while enabling revenue streams from pulp, biomass, and panel production.

Industrial-Grade Standardization

Delivers chips with precision dimensions (15–20mm length, 3–5mm thickness) at ≥97% qualification rates (disc chippers). Ensures optimal pulp cooking efficiency and uniform board density for MDF/OSB, directly boosting downstream manufacturing yield and quality control.

Eco-Circular Value Chain

Diverts 100% wood waste from landfills, converting it into carbon-neutral biomass fuel (18 MJ/kg), erosion-control mulch, or recycled panel feedstock. Mobile models enable on-site processing, minimizing emissions from transport while supporting circular economy compliance.

Processable Wood Varieties

Output Display

Application Scenarios

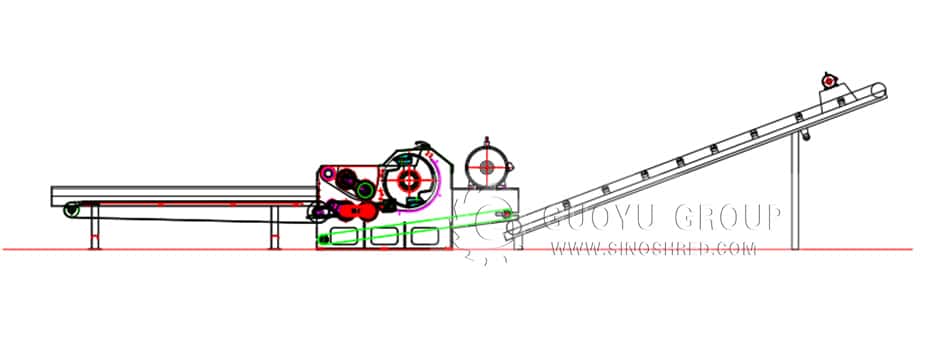

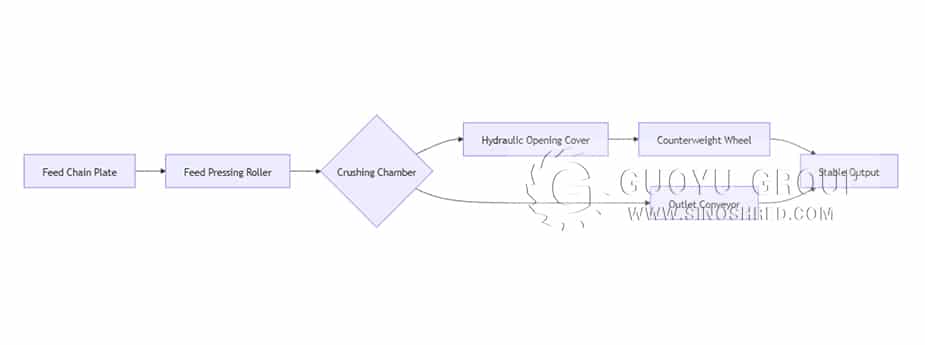

Working Principle

Wood chippers employ a high-torque cutting mechanism (rotating disc or drum) fitted with hardened steel blades. Material enters via a regulated feed system—typically hydraulic rollers that adjust pressure based on log diameter (30–350mm). As wood contacts the spinning blades (960–3000 RPM), it is sheared against a fixed anvil or counter-knife, slicing it into precise chips meeting industrial standards (15–20mm length × 3–5mm thickness).

Cut fragments fall onto a sizing screen; undersized pieces discharge via conveyor/blower while oversized chunks recirculate for recutting. Advanced models integrate magnetic separators to remove metal contaminants (e.g., nails from recycled wood), ensuring purity for downstream processes like pulping or biomass pelletizing.

Product Structure

| Structure | Component Advantage |

| Feed Chain + Roller | Ensures continuous material flow → Prevents jams for branches ≤300mm diameter |

| Hydraulic System | Unifies cover/roller control → Enables one-click maintenance & real-time force calibration |

| Counterweight Wheel | Neutralizes rotational torque → Allows 900-1200 RPM operation without resonance failure |

| Outlet Conveyor | Redirects fragments laterally → Facilitates direct container loading in confined spaces |

Core Advantages

Robust Rotor Core

Engineered with high-inertia construction to absorb extreme impact loads from dense logs and stumps. Its hardened wear-resistant surface minimizes blade degradation, sustaining >95% crushing efficiency over 3,000 operational hours even with metal-contaminated wood.

Heavy-Gauge Cylindrical Barrel

Seam-welded structural steel housing provides unmatched fracture resistance under cyclical stress. Precision-machined inner walls ensure frictionless material flow, eliminating bottlenecks while processing 30+ t/h of irregular demolition debris without distortion.

Engineered Safety Grid

High-visibility red steel mesh blocks projectile debris (>50mm fragments) while allowing real-time visual monitoring. Aerodynamic perforations dissipate heat 40% faster than solid shields, enabling continuous operation in 45°C ambient temperatures compliant with ISO 13857 safety standards.

Precision-Manufactured Components

Laser-calibrated tooling points and weight-optimized holed plates ensure micron-level assembly tolerances (±0.2mm). Color-coded segments accelerate field maintenance by 70%, while thermal-relief holes extend bearing lifespan 2x in high-dust environments.

Technical Specifications

Drum Wood Chipper Specifications:

| Parameter | Model GY-215 | Model GY-216 | Model GY-218 | Model GY-2113 |

| Inlet Size (mm) | 160×400 | 230×500 | 300×680 | 450×700 |

| Capacity (t/h) | 3-4 | 7-8 | 10-15 | 15-20 |

| Main Motor Power (kW) | 45 | 55-60 | 90-110 | 132-160 |

| Feed Roller Power (kW) | 2.2+3 | 3+4 | 4+5 | 7.5×2 |

| Oil Pump Power (kW) | 0.75 | 0.75 | 0.75 | 0.75 |

| Machine Weight (T) | 3 | 4.1 | 6.9 | 11.5 |

Disc Wood Chipper Specifications:

| Model | Throughput(t/h) | Required Power(kW) | Weight(kg) | Disc Diameter(mm) |

| GY-800 | 3-6 | 22-30 | 550 | 740 |

| GY-950 | 5-8 | 30-37 | 800 | 900 |

| GY-1100 | 6-9 | 37-55 | 1,650 | 1,050 |

| GY-1210 | 8-10 | 75 | 2,100 | 1,200 |

| GY-1410 | 10-12 | 90 | 2,800 | 1,400 |

Mobile Integrated Wood Chipper Specifications:

| Model | GY1400-800 |

| Cutter Drum Diameter (mm) | 1,050 |

| Cutter Drum Speed (rpm) | 900 |

| Rotor Type | 4-knife rotor or 24 tiger claws |

| Screen Diameter (mm) | 90 |

| Infeed Conveyor Motor (kW) | 11 |

| Feed Roller Motor (kW) | 7.5 |

| Hydraulic System Motor (kW) | 4 |

| Main Motor Power (kW) | Diesel Engine 618, 340 kW |

| Discharge Conveyor Motor (kW) | 5.5 + 11 |

| Magnetic Separator Motor (kW) | 3 |

| Infeed Conveyor Length (mm) | 6,000 |

| Discharge Conveyor Length (mm) | 10,000 |

| Output Size (mm) | ≤80 |

| Capacity (t/h) | 25-30 |

| Inlet Size (mm) | 1,400 × 800 |

| Machine Weight (t) | 26 |

| Dimensions (m) (L×W×H) | 9.9 × 3.0 × 3.3 |

Building Template Crusher Specifications:

| Model | Main Power(kW) | Infeed Size(mm) | Weight(t) | Capacity(t/h) |

| GYSQ1300 | 55+5.5+4 | 1300×300 | 4.5 | 5–8 |

| GYSZ1300 | 75+5.5+4 | 1300×300 | 7.5 | 6–10 |

| GYSQ1500 | 110+7.5+5.5 | 1500×400 | 9 | 8–15 |

| GYSZ1500 | 132+7.5+5.5 | 1500×400 | 11.8 | 12–16 |

Tree Stump Crusher Specifications:

| MODEL | GY-JP5000 | GY-JP7000 |

| Dimensions(L*W*H) | 9700mm×3000mm×3650mm | 10500mm×3000mm×3650mm |

| Weight | 15.6Tons | 16.8Tons |

| Capacity | 15-30T/H | 25-40T/H |

| Maximum Processing Diameter | 1800mm | 2400mm |

| Spindle Working Speed | 900RPM | 900RPM |

| Engine Power | 380Hp | 420Hp |

| Fuel Tank Volume | 300L | 300L |

| Maximum Fuel Consumption | 30L/H | 35L/H |

| Cutting Roller Size | 1100mm×700mm | 1530mm×700mm |

Shipment Display

Case Study

Why Choose Guoyu Machinery

- Embedded Metal Tolerance (≤10mm):

Guoyu crushers process wood with embedded nails/rebars up to Φ10mm and steel plates ≤3mm—5x thicker than industry standards. Our patented anvil-block reinforcement and hardened hammer design prevent damage, cutting tool replacement costs by 70% in demolition recycling.

- Closed-Loop Magnetic Purification:

Integrated permanent magnet separators remove ≥97% of ferrous contaminants during crushing—versus competitors requiring post-process screening. This boosts throughput by 30% while eliminating downstream equipment damage risk, ensuring sludge-free pulp/OSB production.

- Gen-5 Hydraulic Intelligence:

Fifth-generation models auto-adjust feed pressure/torque via load-sensing hydraulics. Crushes Φ400mm logs to uniform 8-100mm fragments in one pass, reducing re-crush energy by 50% vs. conventional crushers. Anti-jam reversal extends operation cycles to 6,000h without shutdown.

Manufacturing

GUOYU integrates advanced casting and forging processes to produce mission-critical shredder components. Our foundry utilizes sand casting (up to 6-ton parts) and precision investment casting for complex geometries.

Service

At GUOYU, our end-to-end partnership model transforms how you experience industrial machinery. We begin long before installation—collaborating to engineer solutions that precisely align with your operational targets and site constraints.