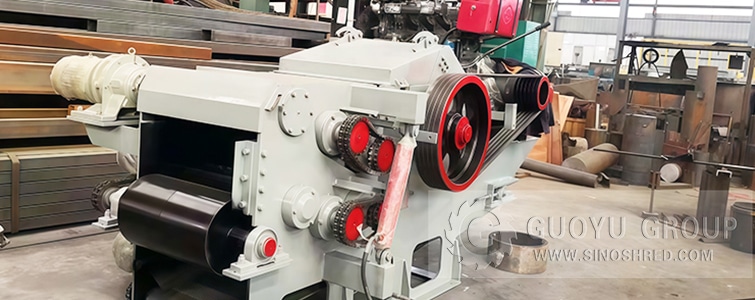

Wood Log Debarker

Effortless Branch Disposal. Instant Biomass Productivity

【Feed Size】: 20-500 mm

【Capacity】: 9-12t/h

【Application】:Wood board skins, wood veneers, cotton stalks, various crop straws, etc.

【Power】: Available in Diesel Engine & Electric Motor options.

Technique Principle

The debarker employs a rotating drum with hydraulically controlled four-edge knives mounted radially. Logs are fed into the drum through an infinitely variable speed conveyor, adapting to log diameter (including frozen/curved wood). As the drum rotates clockwise, logs tumble while knives shear bark via calibrated blade pressure. Bark removal occurs through:

- Impact friction (log-on-log tumbling)

- Precision scraping (knives contouring to wood grain)

- After 15 minutes, the drum reverses rotation (counterclockwise) for 2 minutes, ejecting debarked logs via centrifugal force. The knife pressure optimization + reverse-cycle ejection achieves >95% bark removal with minimal wood damage.

Types of Machine For Sale

Wood Log Debarker

Guoyu Wood Log Debarker efficiently strips bark from logs up to 95%+ purity using hydraulically controlled four-edge knives in a rotary drum. Designed for heavy-duty operation, it handles frozen, curved, and dense woods (eucalyptus, oak) with variable-speed feeding. Automated clockwise debarking and counterclockwise ejection ensure minimal wood damage – reliably replacing manual labor in pulp, paper, and lumber mills.

Wood Log Debarker

Guoyu Wood Log Debarker efficiently strips bark from logs up to 95%+ purity using hydraulically controlled four-edge knives in a rotary drum. Designed for heavy-duty operation, it handles frozen, curved, and dense woods (eucalyptus, oak) with variable-speed feeding. Automated clockwise debarking and counterclockwise ejection ensure minimal wood damage – reliably replacing manual labor in pulp, paper, and lumber mills.

Key Features

Four-edge tungsten knives with hydraulic pressure modulation (180–380 bar) automatically contour to logs – from frozen oak to knotty eucalyptus. Maintains consistent bark shear force while reducing wood damage <1%, even for curved/irregular timber.

Infinitely variable conveyor (4–12 m/min) adjusts feed rate in real-time for challenging woods (frozen birch, dense Ulmus). Ensures >95% debarking rate without overloading, cutting energy waste by 30% vs. fixed-speed systems.

Automated reverse rotation (counterclockwise) engages post-debarking to eject logs and clear accumulated debris (bark, silica). Zero manual intervention – processes next batch in <2 mins while extending knife life 2x.

Key Features

Intelligent Hydraulic Knife Control

Four-edge tungsten knives with hydraulic pressure modulation (180–380 bar) automatically contour to logs – from frozen oak to knotty eucalyptus. Maintains consistent bark shear force while reducing wood damage <1%, even for curved/irregular timber.

Adaptive Variable-Speed Feeding

Infinitely variable conveyor (4–12 m/min) adjusts feed rate in real-time for challenging woods (frozen birch, dense Ulmus). Ensures >95% debarking rate without overloading, cutting energy waste by 30% vs. fixed-speed systems.

Self-Cleaning Drum Cycle

Automated reverse rotation (counterclockwise) engages post-debarking to eject logs and clear accumulated debris (bark, silica). Zero manual intervention – processes next batch in <2 mins while extending knife life 2x.

Processable Wood Varieties

Output Display

Application Scenarios

Working Principle

Raw logs (including frozen, curved, or dense species like eucalyptus, oak, or birch) are fed into the debarker via an infinitely variable-speed conveyor, which automatically adjusts the feed rate (4–12 m/min) based on log diameter and wood density. Upon entering the rotating drum, logs undergo clockwise tumbling at 8–12 RPM for precisely 15 minutes.

During this phase, dual debarking mechanisms work simultaneously: kinetic collisions between logs dislodge bark through impact friction, while hydraulically controlled four-edge knives (maintaining 180–380 bar pressure) scrape residual bark by dynamically contouring to each log’s surface curvature. Following debarking, the drum instantly reverses rotation to counterclockwise at 10–15 RPM for exactly 2 minutes.

This centrifugal phase actively ejects bark-free logs through discharge gates while purging all debris (bark fragments, silica, grit) through integrated screening slots. The system self-resets within seconds, enabling continuous batch processing with zero manual intervention. Output achieves >95% bark removal purity and <1% wood surface damage – ready for pulp milling or precision lumber processing.

Product Structure

| Structure | Function |

| Abrasion-Resistant Drum | Rotating chamber (Ø1.5–2.5m; L=4–8m) with internal lifters for log tumbling |

| Hydraulic Knife Arms | 4–8 arms with pressure sensors; tungsten blades replaceable in ≤5 mins |

| Counter-Rotation Gearbox | Enables instant shift from 12 RPM clockwise → 15 RPM counterclockwise |

| Variable-Speed Infeed | Chain/belt conveyor with load-sensing hydraulics; handles Ø100–500mm logs |

| Debris Ejection Ports | Slotted screens + air-knife system for 100% bark/sand removal |

| Base Frame | Fabricated steel (H-beam construction) with vibration dampeners |

Core Advantages

Frame Assembly: Precision-Accommodating Structure

Welded joints feature machined contact surfaces

Ground-flange interfaces with micro-serrated textures ensure zero-slip clamping force distribution under torsion. Stress-relieved welds eliminate fatigue concentration.

Conveyor Roller: Sealed Bearing Longevity System

Dual labyrinth seals with grease-purge channels

Radial lip seals rotate within vapor-barrier sleeves, preventing grit ingress while allowing thermal expansion – critical for swampy/muddy environments.

Soil Tines: Fatigue-Resistant Geometry

Asymmetric tip beveling reduces drag spikes

Curved neck profiles dissipate shock waves away from mounting bases. Hardness gradients (tip-to-root) prevent brittle fractures in rocky soils.

Drive Shaft: Harmonic Vibration Mitigation

Polygon shaft milling eliminates resonance points

Hexagonal profile disrupts harmonic frequencies at 200-800Hz – the primary failure range for PTO systems – dampened further by weighted guard panels.

Gauge Wheel: Terrain-Adaptive Contact Patch

Crowned tread with variable-density rubber

Center-reinforced lugs (90 Shore A) provide traction, while softer shoulder ribs (70 Shore A) conform to uneven terrain – reducing compaction without sacrificing depth stability.

Quick-Hitch: Zero-Tolerance Alignment System

Conical locating pins with wear-compensation

Tapered pin geometry centers implements within ±0.5mm, while graphite-impregnated bushings accommodate frame flex without backlash.

Technical Specifications

| Model Type | GY-S800 |

| Wood Diameter (mm) | 400-800 |

| Wood Length (m) | 0.5-2 |

| Capacity (T/H) | 15-18 |

| Debarking Rate (%) | Fresh log >95% Dry log >90% |

| Roller Diameter (mm) | 710 |

| Roller Rotational Speed (rpm) | 180 |

| Roller Length (mm) | 5000 |

| Power (kW) | 30 × 2 |

| Weight (t) | 8 |

| Dimensions (L×W×H) (m) | 6 × 2.5 × 2 |

Why Choose Guoyu Machinery

- Industrial-Scale Efficiency & Output:

With dual 30kW motors powering optimized rollers, it processes 15–18 tons of logs hourly – equivalent to 50+ manual workers. The 180 rpm roller speed ensures swift material handling, minimizing downtime in high-volume pulp/paper mills.

- Unmatched Debarking Precision & Adaptability:

Hydraulic roller pressure dynamically adapts to log profiles (knots/curvature), achieving >95% efficiency on fresh logs and >90% on dry timber. Processes diverse sizes (0.5–2m length, 400–800mm Ø) without recalibration – ideal for mixed-species forestry operations.

- Heavy-Duty Engineering & Space Optimization:

710mm Ø × 5000mm rollers (total 3.54㎡ contact area) maximize bark-stripping force while resisting deflection. Despite an 8-ton weight, its layout minimizes floor space – enabling integration into existing production lines without facility modifications.

Manufacturing

GUOYU integrates advanced casting and forging processes to produce mission-critical shredder components. Our foundry utilizes sand casting (up to 6-ton parts) and precision investment casting for complex geometries.

Service

At GUOYU, our end-to-end partnership model transforms how you experience industrial machinery. We begin long before installation—collaborating to engineer solutions that precisely align with your operational targets and site constraints.